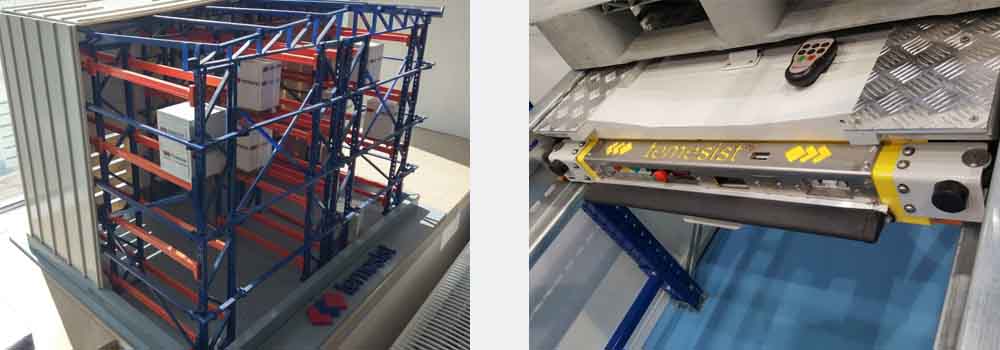

Clad Rack System

Clad Rack Building system

As the name itself indicates Self Cladding System is constructed by using racking as support structure. Once the racking is formed it is cladded all around to form walls and roof. It will also have provision to facilitate fire fighting systems, electrical systems and other miscellaneous requirements, that are necessary to construct a full fledged warehouse.

Many factors are taken into account to construct such a warehouse. They are vertical and axial wind force, stability and other safety norms.

Radio Shuttle System

The Radio Shuttle System will save you both time and space…

Shelves along the installation and facilitating the evacuation of products with automatic carrier high density storage system. In addition the operator can use a few unit remote control for radio control movements shuttle. Shuttle is able to stock a pallet in the last Available position of the rack.

Can handle different sizes with travel speed up to 1m/min and loads up to 1.500 kg. Can be handled manually using a conventional forklift. Installation is a matter of a few minutes. Has its control unit and electrical supply system.

Advantages:

Compared to the classical solutions DRIVE IN, DRIVE THROUGH gravity

Operator busy time can be reduced up to %50.

Maximum utilization of storage capacity with electronically checks of pallet handling.

Lower risk of errors due to operator handling.

Reduction of maneuver for forklift operations.

Can run Automatic version without the need of operator